Höga krav - vår vardag

Quality

Quality is a complex area where it is important to stay up-to-date; therefore, we follow the development of current standards, industry practices, and handle specific customer requirements daily.

Since a large part of our production is related to the pharmaceutical industry, we have a good understanding of the requirements in ASME's Bioprocessing Equipment directive, ASME-BPE. Other standards that affect our operations include, for example, surface treatment, pressure vessels, and various requirements within electrical and automation.

Group-Wide Quality Policy

The Nordholm Group shall be the leading contract manufacturer in Sweden of mechanically processed and welded industrial components as well as complete process modules. Our strength lies in industries with high demands such as pharmaceuticals, food, and other industries with similar requirements.

Med hållbar effektivitet genom perspektiven; kund, kvalitet, effektivitet, medarbetare och ekonomi åtar vi oss att ständigt utveckla våra produktionsmetoder och våra verksamheter i enlighet med tillämpliga krav.

We strive to always deliver the right quality at the right time.

ISO 9001 & ISO 3834-2 (Certificates ISO 9001 & ISO 3834-2)

Most people know that ISO 9001 is a cross-functional quality management system, but as a welding company it is ISO 3834 that handles the welding-related questions, -2 means that we are certified against the highest requirements and we achieved this already in 2007. The certification according to ISO 3834-2 means that we have technically documented competence but also that we ensure that we have the correct equipment to enable the work and lay the foundation for the right quality.

Regarding ISO 9001, we now have an approved, group-wide management system. This means that both Nordholms and OMEK's operations are certified.

Knowledge of customers' processes is a prerequisite for being a supplier to the most demanding industries. We are happy to work with our customers at an early stage to provide input from a manufacturer's perspective. We have several examples of how we, together with customers, have developed new solutions to streamline production processes and at the same time ensure good quality

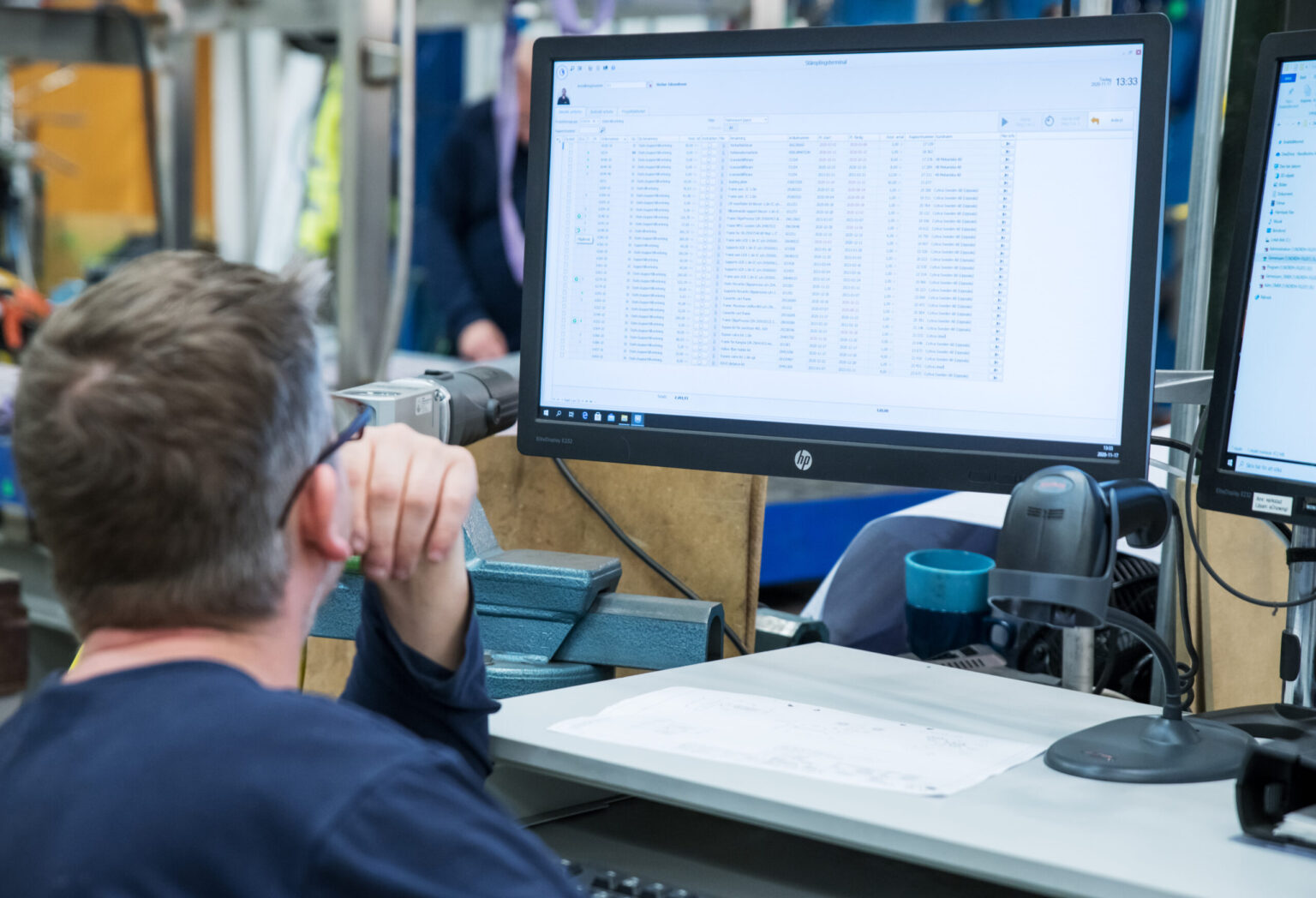

Traceability & identity

Meeting the requirements for traceability and identity is a prerequisite for being able to deliver to the pharmaceutical and food industries, and this process starts already at the order placement stage. Incorrect requirements in our purchases risk jeopardizing an entire project.

When a delivery arrives, the material and documentation are checked before approval, and the items are handled with traceability in our business system. All material withdrawals are documented, and when material is divided, the batch number is transferred to the cut piece.

The reporting documents generated in our various production stages are compiled according to customer requirements and delivered together with the product to the customer.

Quality controls

In the different production steps, several different controls are performed such as:

- Ra-meassuring

- Visual control

- Geometry measurements

- Fiber optic control

- Pressurization

- Leak testing

- Penetrant test

In cases where third-party inspection is required, we collaborate with accredited control companies.

Pressurization (Certificate of Accreditation ISO/IEC 17020 (C))

Nordholms is accredited by Swedac for pressurization with gas according to ISO/IEC 17020. As a type C inspection body, we can perform inspections both on our own installations or on installations made by another manufacturer/installer.

Machines and equipments

Achieving good quality and efficiency requires a combination of knowledge, experience, and good tools. Therefore, in recent years, we have made significant investments in machinery and equipment in both sister companies OMEK and Nordholms.